Typical catalysts are the cobalt carboxylates (known as cobalt soaps).

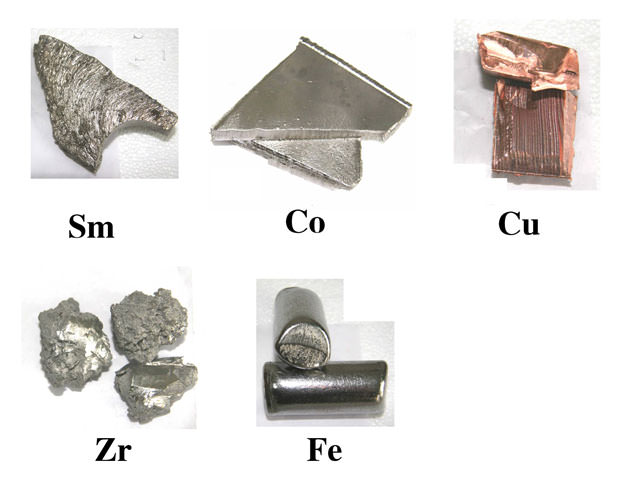

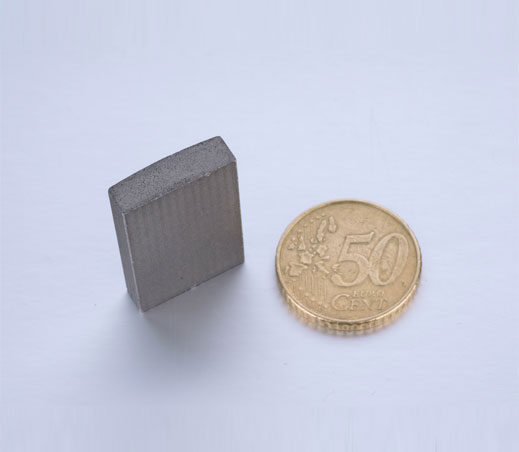

Several cobalt compounds are oxidation catalysts. Moreover, they have excellent corrosion resistance at high temperatures (980-1100 ☌) because of their higher chromium contents. They possess better weldability and thermal fatigue resistance as compared to nickel based alloy. The common grades for Samarium Cobalt magnets are 16, 18, 20, 22, 24, 26, 28, 30, and 32. Again, like neodymium magnets, the higher the number, the stronger the magnet. They are well suited for technical applications where high-performance and magnetic strength is required in very high or low temperature environments. For Samarium Cobalt (SmCo) Magnets, the BHmax will range from 16 MGOe to 32 MGOe. While not used commercially to the extent of Ni-based superalloys, alloying elements found in research Co-based alloys are C, Cr, W, Ni, Ti, Al, Ir, and Ta. Samarium Cobalt (SmCo) magnets have excellent temperature stability while maintaining their magnetic properties in extreme temperature conditions. Unlike other superalloys, cobalt-base alloys are characterized by a solid-solution-strengthened austenitic (fcc) matrix in which a small quantity of carbide is distributed. discovered a new phase in the Co–Al–W system. (The Expresswire) - The Samarium Cobalt Magnet Market (2023-2030) Latest Research Report provides an. Cobalt is primarily used in lithium-ion batteries, and in the manufacture of magnetic, wear-resistant and high-strength alloys. The MarketWatch News Department was not involved in the creation of this content. Cobalt has been used in many industrial, commercial, and military applications.

0 kommentar(er)

0 kommentar(er)